AutomatiON AND ROBOTIZATION

Automation and robotization open the door to endless possibilities of streamlining work processes and increasing productivity, but at the same time they require wise leadership and human creativity for their successful integration into modern companies.LIFTEC – The difference is in the approach!

We are the ideal partner for developing the automation of your operations in the following areas:

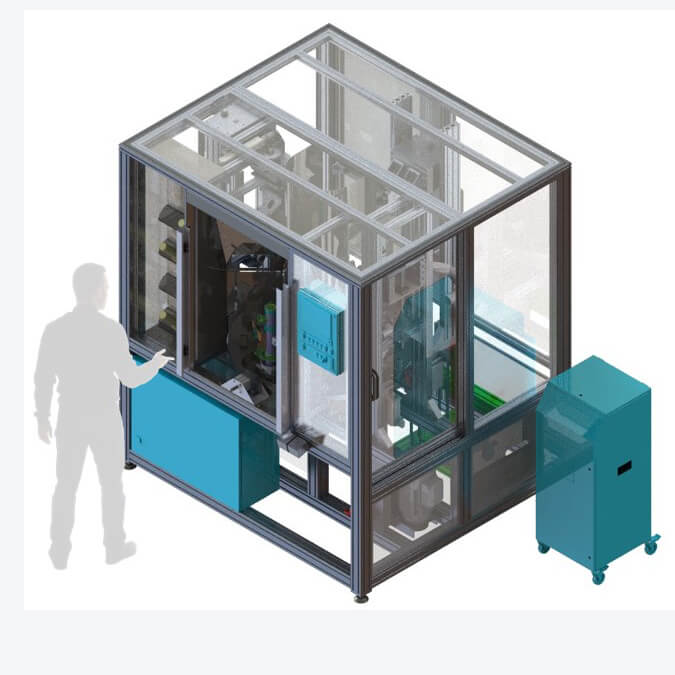

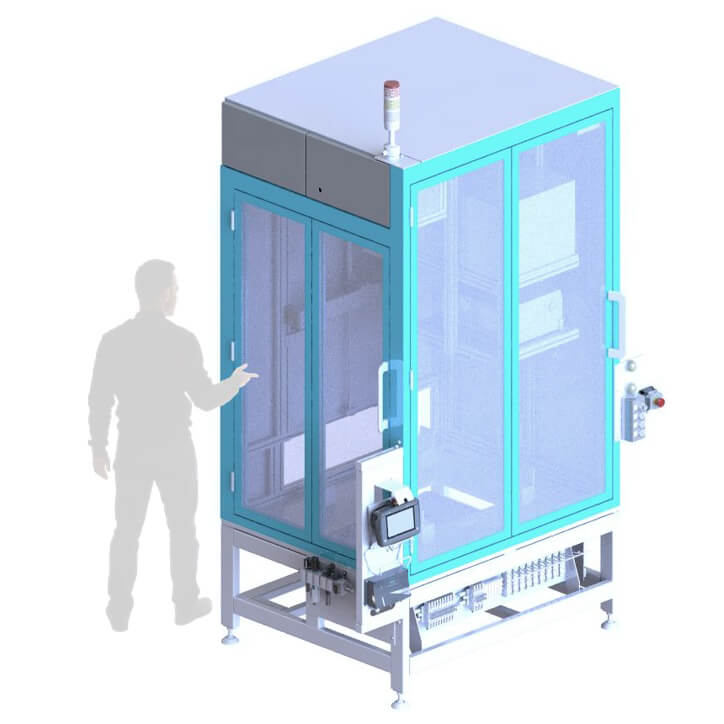

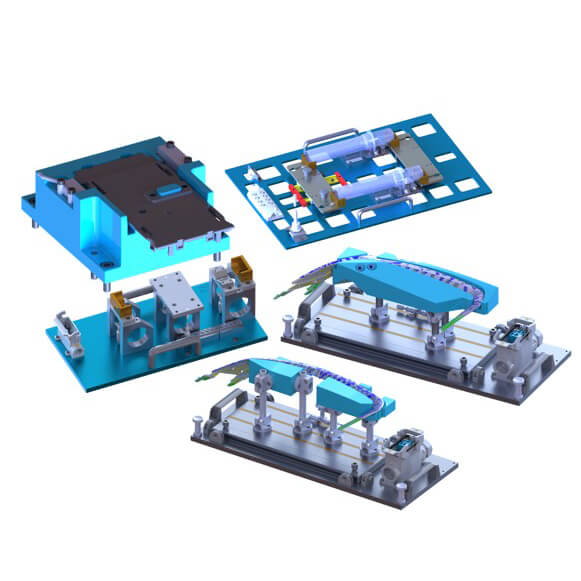

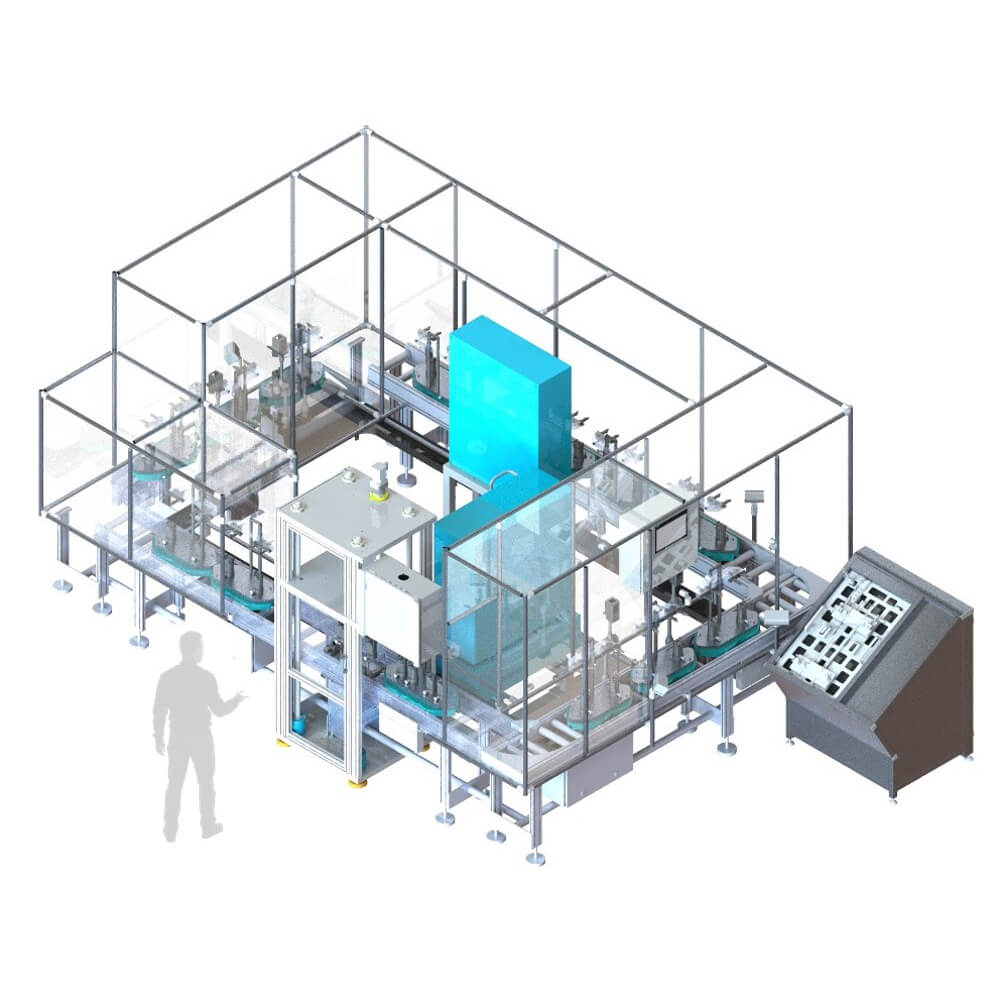

Complete production of automated, robotic workplaces and single-purpose devices.

Comprehensive solutions for product marking, identification, tracking and inspection (traceability).

Optimizing the efficiency of the marking process

in every industry.

Automation of all portfolio labeling technologies

LIFTEC.

Solutions for monitoring, identification and control of production quality.

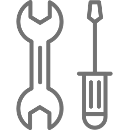

Vibrating Feeder

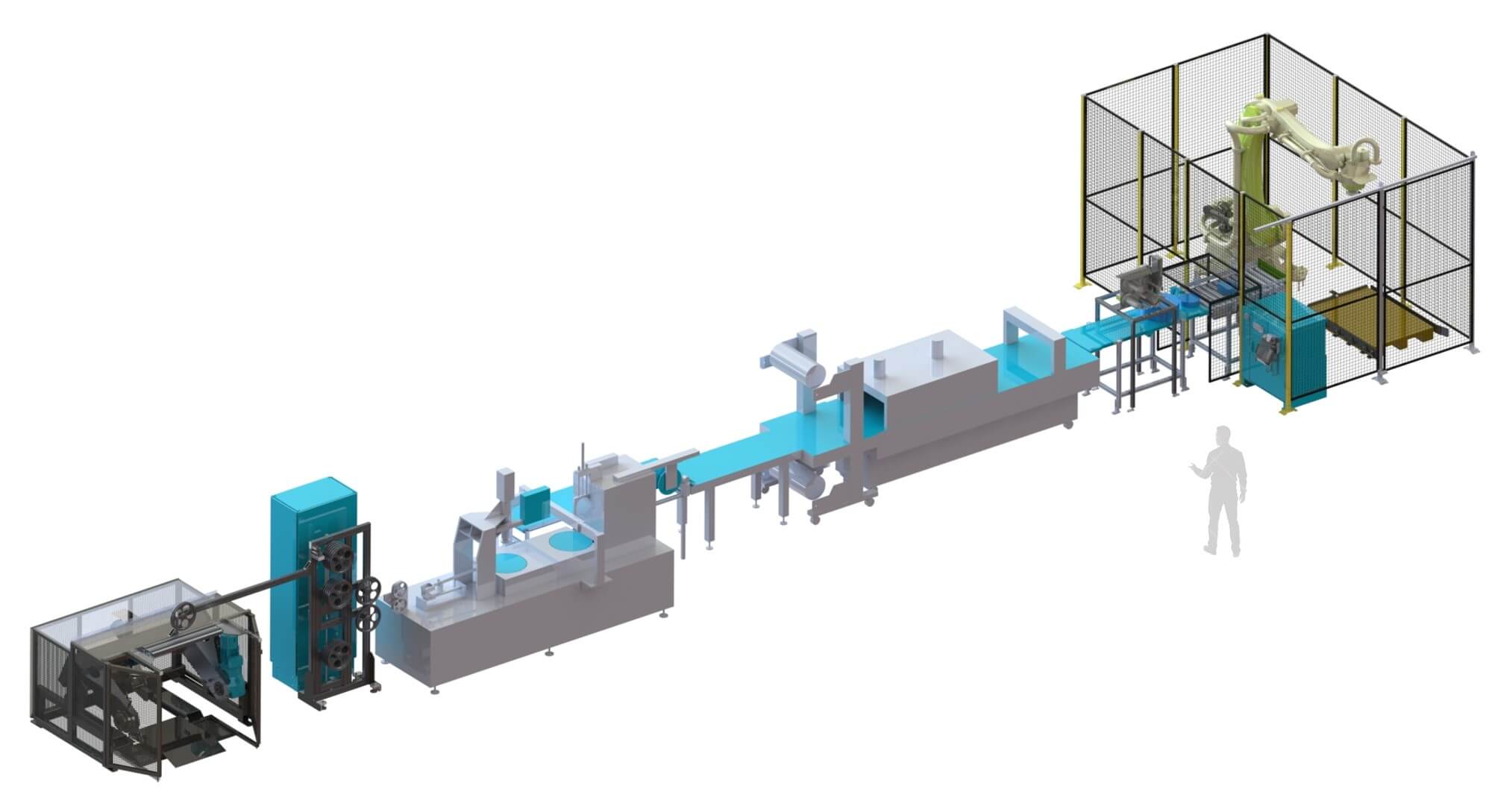

Integration of the micro-punch into the line

Application of liquids

Pneumatic screwdriver

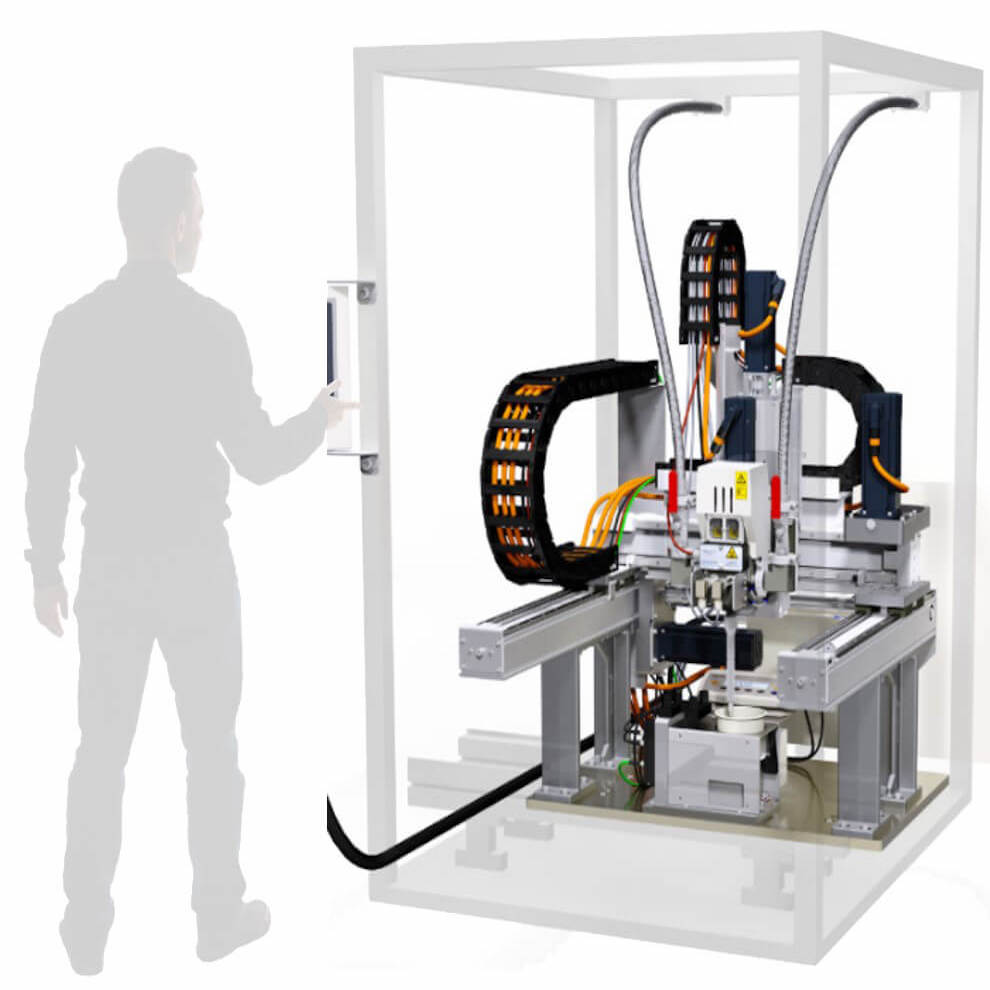

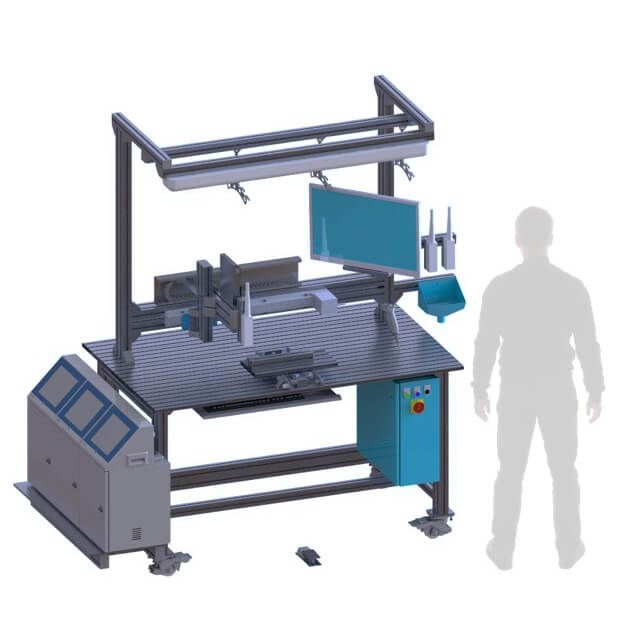

Desktop Marking Station

Laserová pracovná stanica

Laser Workstation

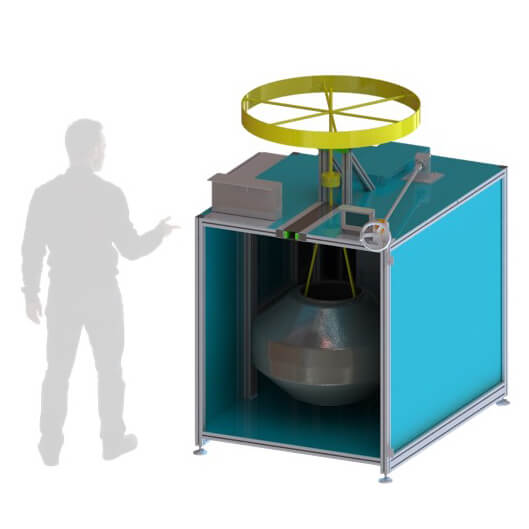

Carousel station

Membrane marking

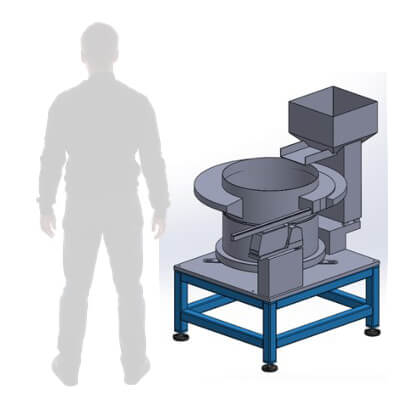

Electric handling axle

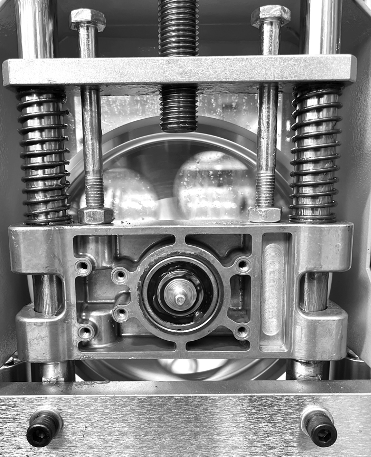

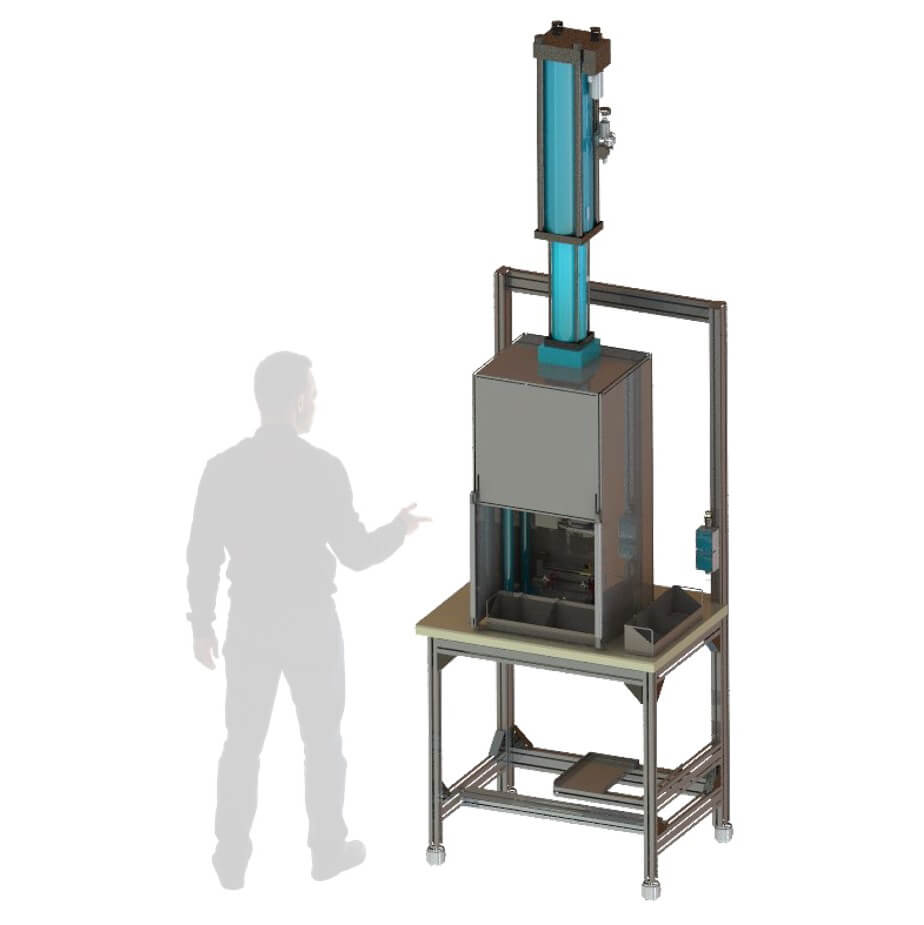

Press station

Workstation

Conveyor

Workstation

Conveyor

Workstation

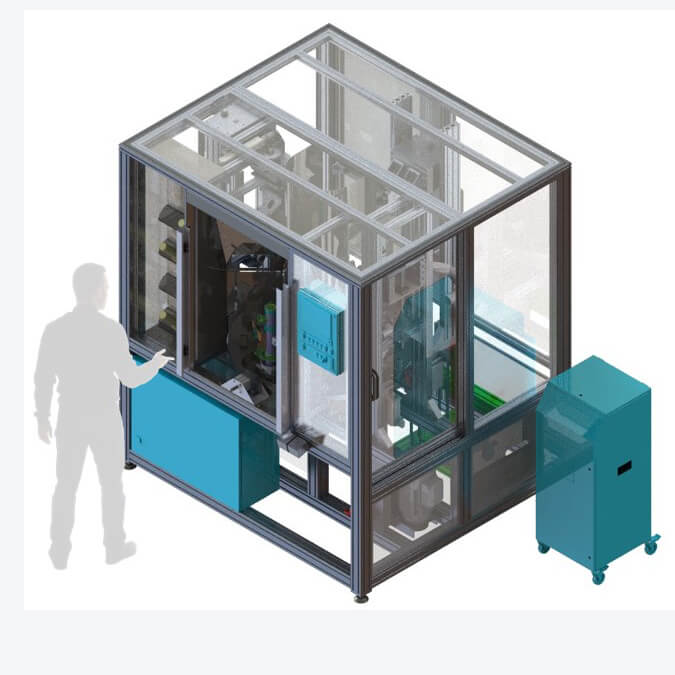

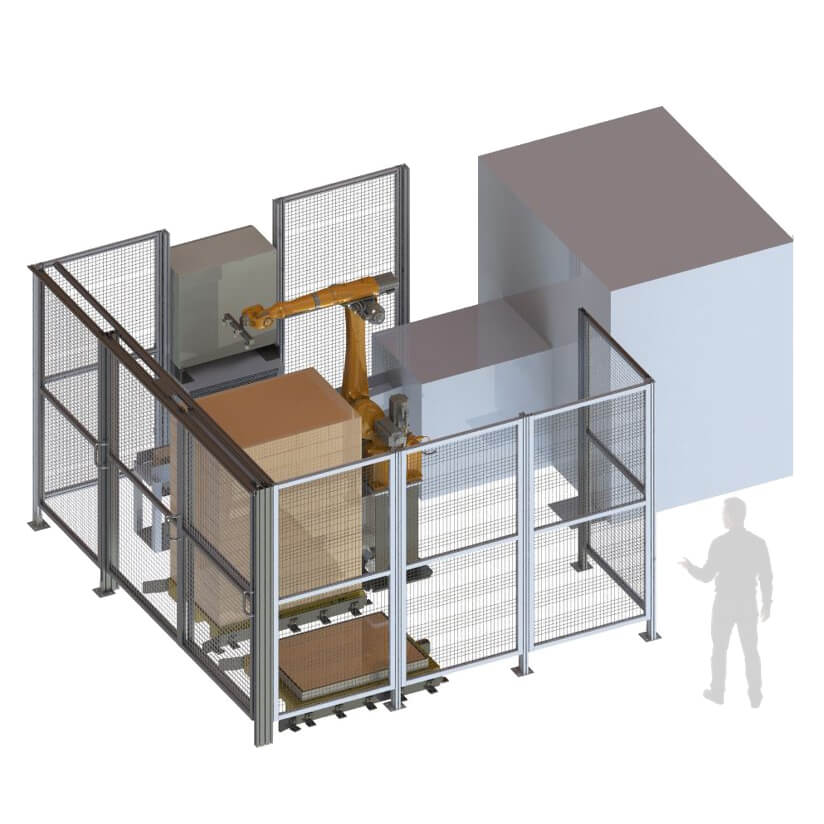

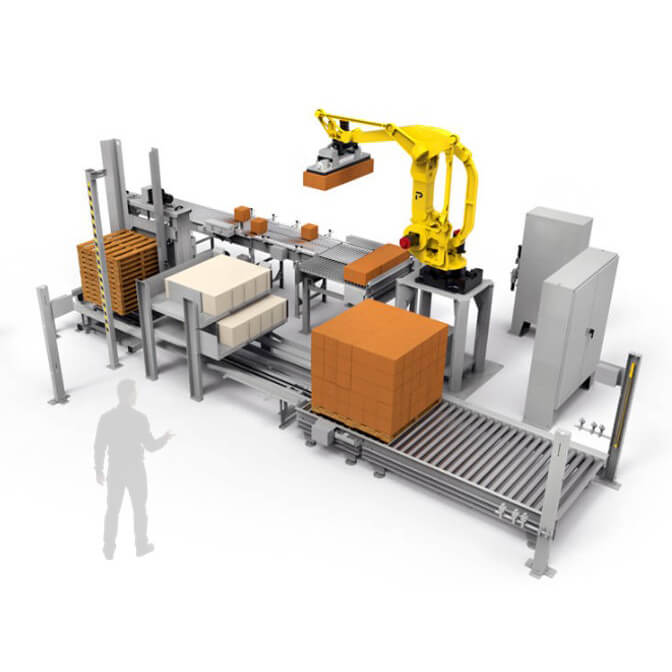

Robotic Cartoning Machine

Poka Yoke solution

Manually operated assembly lines

Robotically operated assembly lines

Conveyor systems

Complete cable rewinding line