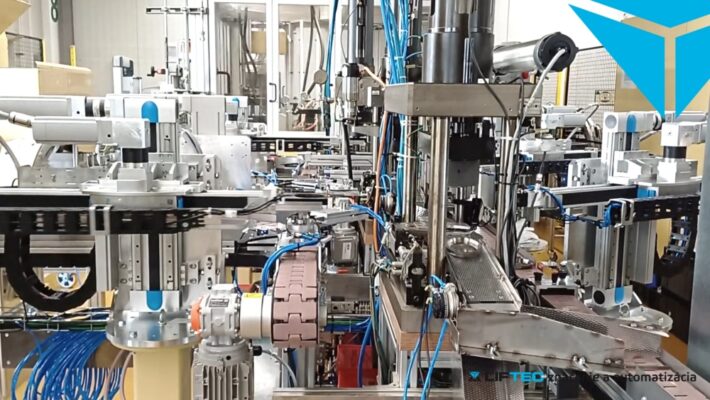

Automation in industry brings revolutionary changes that increase the efficiency and quality of production processes. We designed and implemented a fully automated bearing assembly line for our customer, which specializes in the production of bearings for gearboxes. The goal was to increase speed, quality, efficiency and competitiveness in the distribution of spare parts to the end customer.

Original manual process

Initially, the bearings were assembled manually at five pressing stations. Each station was manned by an operator who gradually pressed out and assembled the bearings. This process was time consuming and required a high level of skill and precision from the operators. Only the size and quality control was automated, which meant that most of the work was done manually.

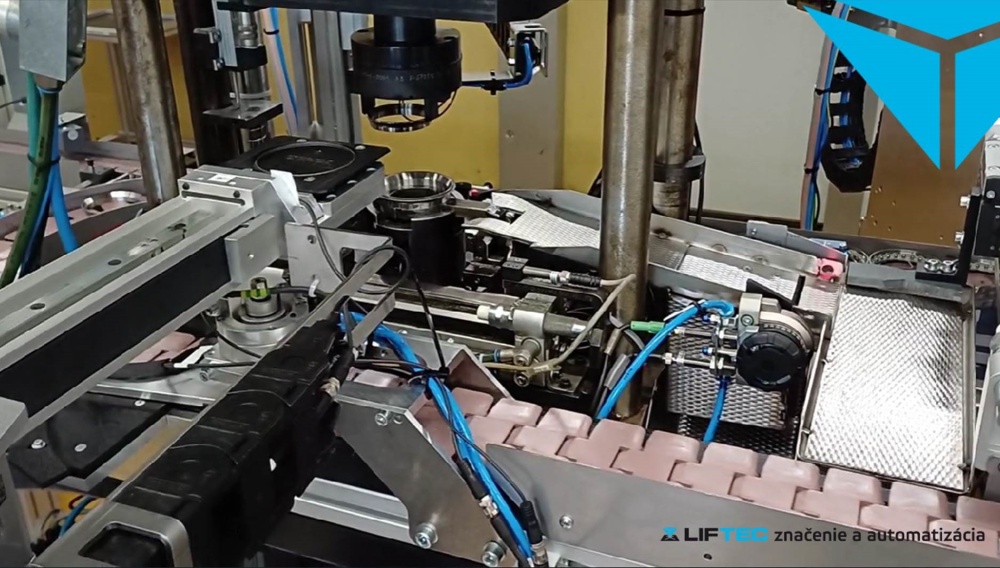

Press automation and conveyor integration

Our goal was to automate the presses and integrate them into one continuous line. The process involved connecting the presses with conveyors and adding manipulators to put pieces into and out of the press. In this way, we created a self-service automated line that is connected to the central WMS system. This system enables efficient management and monitoring of production processes.

Challenges and solutions

One of the biggest challenges was testing the bearings for the beds that we created using 3D printers. This process required dozens of tests to achieve perfection. Thanks to our persistence and innovative solutions, we managed to create bearings that meet the highest quality standards.

The benefits of automation

Automating the bearing assembly line has brought many benefits. Productivity increased and labor costs decreased. Automation of engineering production also minimized the risk of errors and ensured consistent product quality. Industrial automation of production enabled flexibility and quick adaptation to changes in demand.

Conclusion

Automation of production processes is essential to maintain competitiveness on the market. Our fully automated bearing assembly line is proof that modern technologies can significantly improve production efficiency and quality. We believe that this project will be an inspiration for other companies that decide to invest in the automation of their production processes.