How to solve automation of valve centering and insertion? We have a solution straight from our workshop!

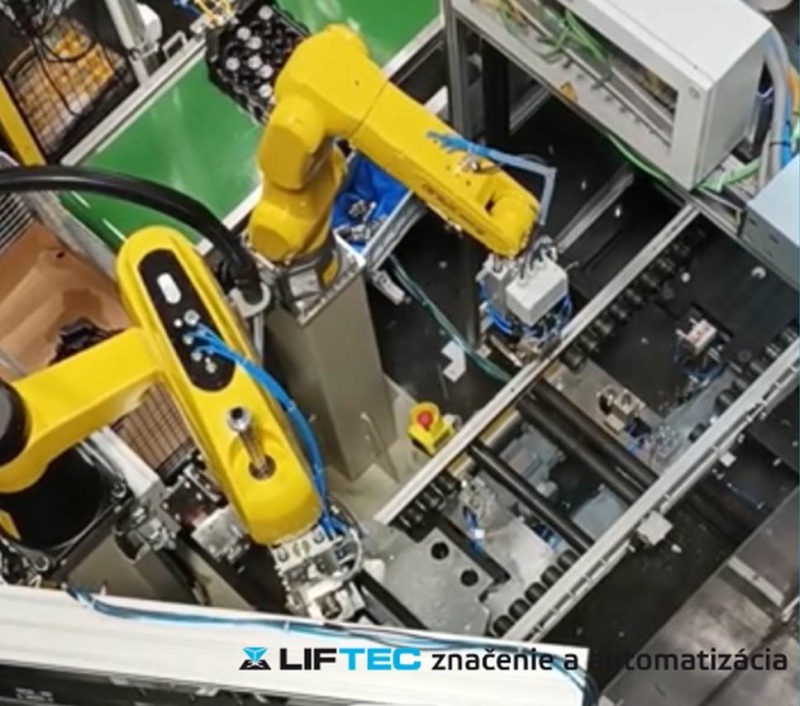

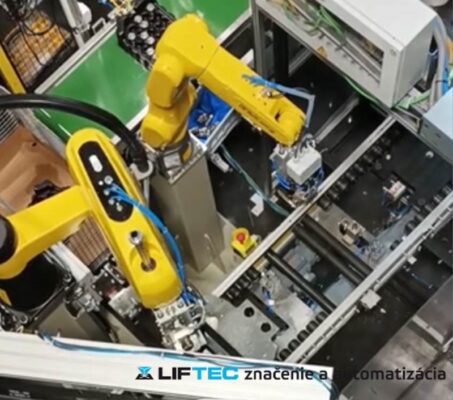

For our customer, we constructed a fully automated line for optimizing the centering of intermediate pipes and inserting valves.

An engineering company that supplies products and systems for the automotive industry and other areas of transportation asked us to supply a fully automated line for optimizing the centering of intermediate tubes for piston rods and subsequent insertion of valves into the centered damper. This project was integrated into the existing production line, which ensured smooth and efficient production.

Process

The project consisted of several interconnected devices, while the main challenge was to achieve absolute precision, at a high speed of feeding valves and placing them on trays. Part of the line was a conveyor on which valves stored in trays were transported. At the precisely determined place, the tray stopped and the valves were photographed by the camera. This camera guided the robot and provided it with information about the exact location of the valve. The SCARA robot, which is known for its high accuracy and speed, ensured the centering of the tubes.

The process was as follows:

- Conveyor: The tray with the valves moved along the conveyor to the designated place.

- Camera: The camera scanned the valve and provided the robot with information about the exact location of the valve.

- Robot: A 6-axis industrial robot took over the valve, inspected it and inserted it into the centered pipes.

Benefits of automation

The implementation of this fully automated line brought several key advantages:

- Automation of engineering production: It ensured high precision and consistent product quality.

- Automation in industry: It increased efficiency and reduced the need for manual work.

- Automation of production processes: Enabled faster and more efficient production with fewer errors.

- Automated production: Reduced operating costs and increased productivity.

- Industrial automation: It ensured better quality control and reduced the risk of human error.

- Industrial automation of production: Enabled the integration of advanced technologies into the production process.

Conclusion

Our company LIFTEC SK is proud to be able to offer innovative solutions that help our clients increase the efficiency and quality of their production processes. A fully automated line to optimize the centering of intermediate tubes for piston rods and insert valves into a silencer is just one of many examples of how technology can transform industries