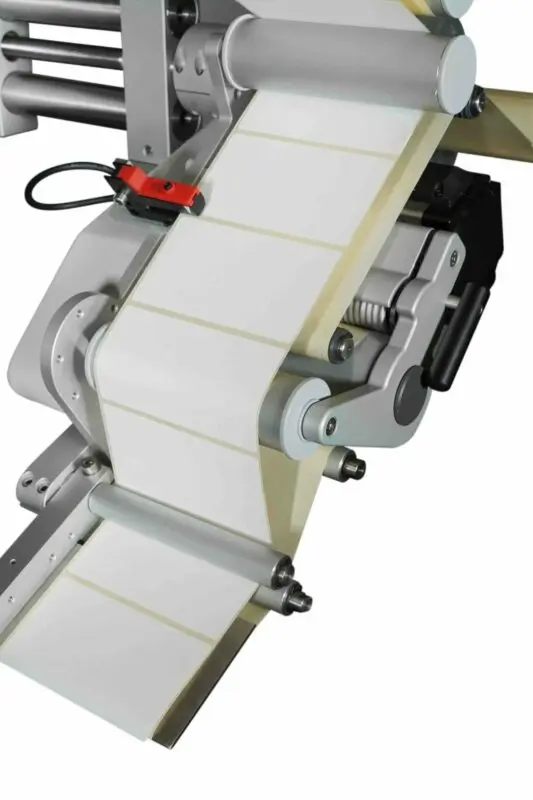

Another group of applicators that you can find in our offer are label applicators without reprinting. Our goal is to provide solutions that make our customers’ processes more efficient. That’s why we cooperate with the company Arca, whose application of labels without reprinting and> are the top in their field. These applicators boast high speed and precision, which is a fundamental prerequisite for a functioning production.

Arca label applicators are designed to minimize space requirements while providing one of the fastest solutions on the market. They are ideal tools for situations where it is necessary to apply a large number of labels quickly and accurately, such as in logistics centers or when packaging products.

Arca’s non-overprint label applicator technology can be integrated into various production lines and automate processes that were previously dependent on manual labor. In this way, they not only save time for their users, but also increase the overall efficiency and reduce the error rate.

Label applicators for various industrial productions

Arca’s wide range of applicators is designed to meet the various needs of industrial production. The basic model is Easy, ideal for smaller operations with a speed of up to 20 m/min. For those looking for more performance, we offer the Dynamic model, which can apply labels at speeds up to 40 m/min and can be easily upgraded from the Easy model.

For advanced applications, there is the Sharp model, which not only achieves the maximum speed of the Dynamic model, but also brings advanced communication functions, including integration with superior systems via the TCP/IP protocol.

At the center of the range are the Evolution and Performance models, which are capable of applying labels at a staggering speed of up to 80m/min, making them the ideal choice for medium to large production lines.

For the most demanding applications, we can offer the Flash and Wind models, which exceed expectations with application speeds above 120 m/min. These models often use the unique technology of nonstop labeling, which means that two identical applicators work in tandem on one line, thus ensuring continuous operation. In the event that one applicator requires a label change, the other takes over, allowing the operator to continue production seamlessly.

This wide range of models ensures that whatever your specific requirements, we have a solution ready to increase the efficiency and productivity of your labeling line.