Main differences between the Roxi and Hermes models

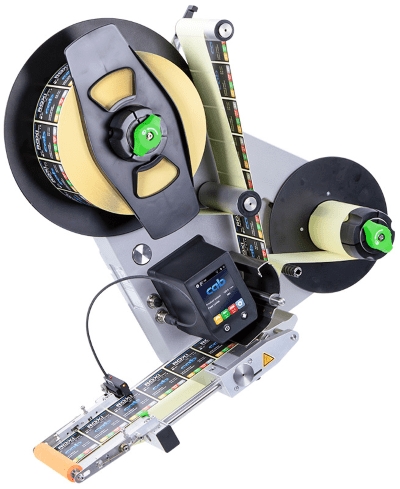

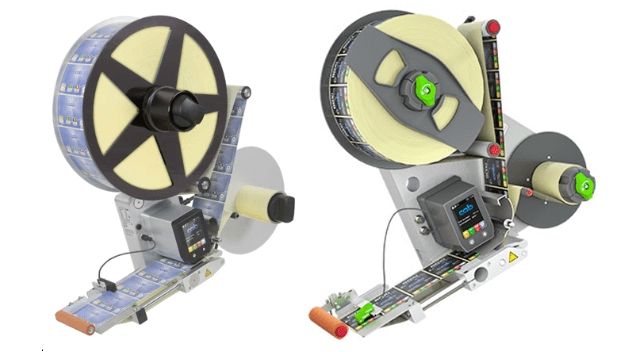

The manufacturer CAB has come to the market with a novelty in the field of label dispensers without reprinting and introduced the ROXI model. The fundamental difference compared to the Hermes applicator is primarily the absence of a print head, even more compact dimensions compared to the Hermes model and the affordability of this solution. The CAB Roxi model is fully configurable and you can choose between the left and right variants and between the maximum width of the applied label 4″ – 6″, or 116 – 176 mm. Roxi applicators are designed for dynamic product labelling (on the move). It is not possible to order the 4014 and 4114 dispensers for these applicators, as in the case of the Hermes model.

Labels and use

The CAB Roxi system has a different role than the CAB Hermes and complements the overall portfolio. Roxi applicators are intended mainly for food, pharmaceutical and FMCG operations, where labels are often already pre-printed. It is not a problem to apply even transparent labels. With Roxi, it is possible to apply labels in sizes from 10 x 10 mm to 176 x 6000 mm. The labelling speed can reach up to 30 m/min, which is enough for most common applications. In case of requirements for faster label application, we can offer the CAB IXOR model, or models from the supplier Arca, which labels at a speed of up to 150 m/min.

Dispensary

Considering the use of the applicator, it is assumed that only so-called “demand modules” will be used. These are peel-off edges with different lengths, widths and functions. The width of these modules can be selected in three variants, from 62 mm through 124 mm to 186 mm in the case of the widest ones. Figure 2.1 shows the simplest version of the direct peel-off module, which does not allow for further adjustment of the labelling angle. Figure 2.2 shows a more sophisticated version, which allows changing the label peel-off angle relative to the product, and Figure 2.3 shows the most universal version of the peel-off edge, which can adapt to different product heights in the range of 10 – 80 mm. The label can be “ironed” on the product with bristles or a foam roller according to the needs of the given application.

Connectivity

Since Roxi is intended for labelling on the move, an encoder can be connected. Thanks to this, the applicator is able to label products even on lines that change their speed. The possibility of communication with Profinet line-establishing systems from Siemens, or the possibility of communication with an OPC UA server, is also very popular. Of course, an integrated web server is then included for the possibility of controlling the entire applicator remotely from any device connected to the same network or via a smartphone. Other communication options are standard Ethernet and Modbus.