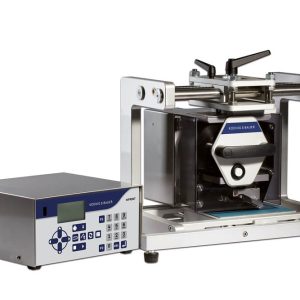

Another use is in addressing envelopes, document personalization or small format printing applications.

Simple operation, high reliability and an attractive price-performance ratio of udaFORMAXX enable wide use in many industries. Thanks to its compact dimensions, it can be used wherever there is not much space available.

The products placed in the input tray are checked by a sensor during removal and are automatically positioned. This guarantees accurate marking with an optional printing system. The technology developed by Koenig & Bauer allows products to be replenished during operation.

The built-in control unit in the udaFORMAXX feeder enables the setting of the feeder’s performance and monitoring of operating parameters directly on the feeder’s built-in display. It is possible to connect a number of marking devices to the feeder, such as: Laser, Inkjet, TIJ, Label Applicator, HRP and many others…

Features:

- Minimum dimensions: 32 x 45 mm

- Maximum dimensions: 372 x 430 mm

- Maximum output: 750 pcs/min

- Feeder speed: 9 – 90 m/min

- Control: Graphic display

- Dimensions: 1300x710x560 mm

- Space for integration of markings: 560 mm

- Weight: 114 kg

- Noise level: 66 db

- Minimum thickness 100g/m2

- Maximum thickness: 5 mm

- Accessories: Stacking conveyor, sorting station, output tray