Silent block marking project

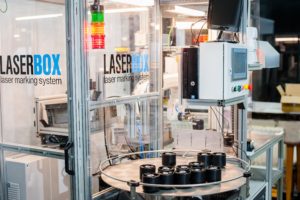

For a major rubber company producing parts for the automotive industry, we custom-made a complex workplace for marking silent blocks – a robotic workstation with a Macsa marking laser. At the beginning of the entire process, the temperature of the products and also the composition of the rubber compound are evaluated based on the color mark recognized by the DATALOGIC camera. Compliant pieces are then marked with a 2D code and serial number using a laser. This is followed by a machine vision legibility test and data storage in the company database. The entire marking process is automated, using the KUKA robot.

Since the laser marking is permanent, its traceability across all production operations is ensured throughout the lifetime of the part. In addition, the 2D code is an ideal solution for ensuring the tracking of the origin of products and preserving the necessary information, which can then be read by machine vision systems.