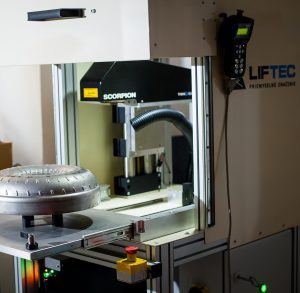

Gearbox parts marking project For a major engineering company that manufactures parts for the automotive industry, where high demands are placed on product quality, we created a complex workplace for marking gearbox parts with a 2D code. When ordering new technology, one of the basic requirements was low noise marking, because, for example, micro impact devices can produce noise up to 70 dB. The choice fell on a laser, which is not only quieter, but also more precise. Since these are large and heavy parts that the operator installs and removes manually, one of the requirements was to facilitate handling. This was ensured by a pull-out mechanism, on which the part is placed and then inserted into the workstation for marking. In this case, the task of marking is to monitor the entire production process in order to minimize the error rate. Since this method of marking is permanent, its traceability across all production operations is ensured throughout the lifetime of the part. In addition, the 2D code is an ideal solution to ensure the tracking of the origin of products and to preserve the necessary information, which can then be read by machine vision systems. After a successful test operation, the workstation was put into production and subsequently the company ordered the production of several other such workstations.

- Difference in approach

-

Newsletter

Odber newsletteru

Prihláste sa na odber newsletteru, aby Vám neunikli žiadne aktuálne a dôležité informácie.

- Difference in approach